What are Power Press Machines?

September 16, 2021

What is a C Type Power Press Machine? & It’s Application

September 20, 2021Pneumatic Press Machine

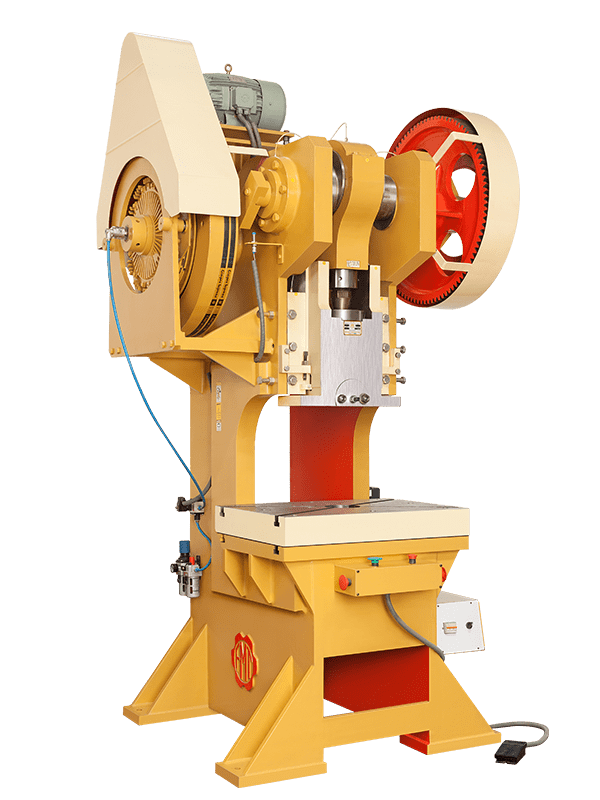

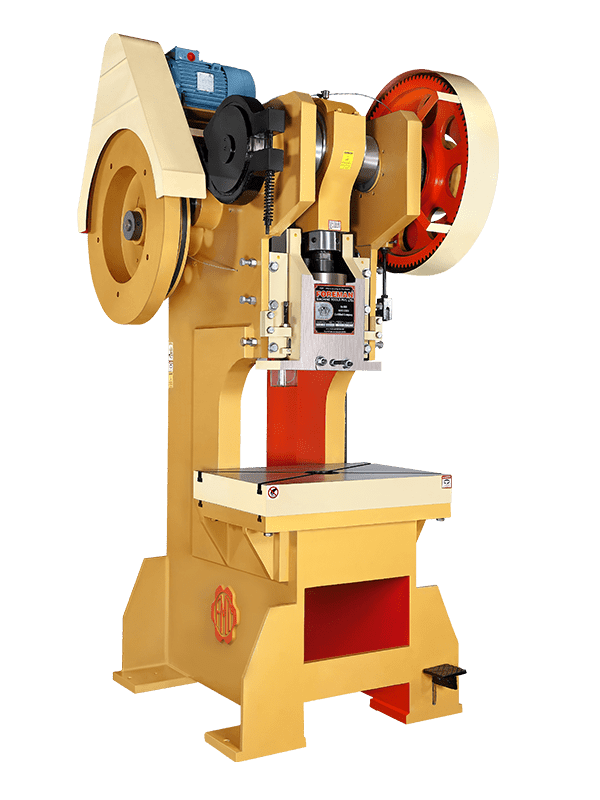

Press machines are utilized in set industrial settings for a large range of uses, including squeezing, forming, and pressing. In a pneumatic framework, compressed air is utilized to send and control powers. In today’s industries, different works are finished by utilizing pneumatic frameworks. Like programmed creation lines, mechanical cinches, controlling train doors, and so on.

There are various types of presses. Pneumatic presses are maintained by the pressurized air. The air is slave into a tube that fills with the air and applies pressure that causes the press to move downwards. Once the press’ stroke is finished, the air is evacuated through valves and mechanical spring elements. The pump moves upwards again.

The pneumatic press’s greatest advantage is its speed. They can change ten times faster than hydraulic presses. They can also stop at any time that the operator opens the tap to release the air.

Pneumatic power presses are quite versatile, able to be placed in a factory in any position in which the operator requires it to be, even upside down. Pneumatic presses are easy to use, and the controls resemble those of more traditional styles of the press.

Advantages

- This system is safer for the operator

- a simple type of automatic accident-avoiding system

- quick in response

- simple in construction

- it is very useful in all industries

- The plan of pneumatic parts is generally straightforward, and they are highly suitable to use in automatic control frameworks.

- All components of a pneumatic system are not expensive, but it’s easily available and hence the maintenance cost is lower than other systems

- Components of pneumatic frameworks are less influenced by different environmental parameters like high temperature, and dust erosion when contrasted with the components of different frameworks.

- That is the reason association is compressed with compacted air supplies and moveable packed. Compress air ought to effectively move from one spot to another, using the pipe. Also, after that used compressed air is delivered into Press Machine in the environment.

Read Blog: What are Power Press Machines?

For more information, Contact Us.