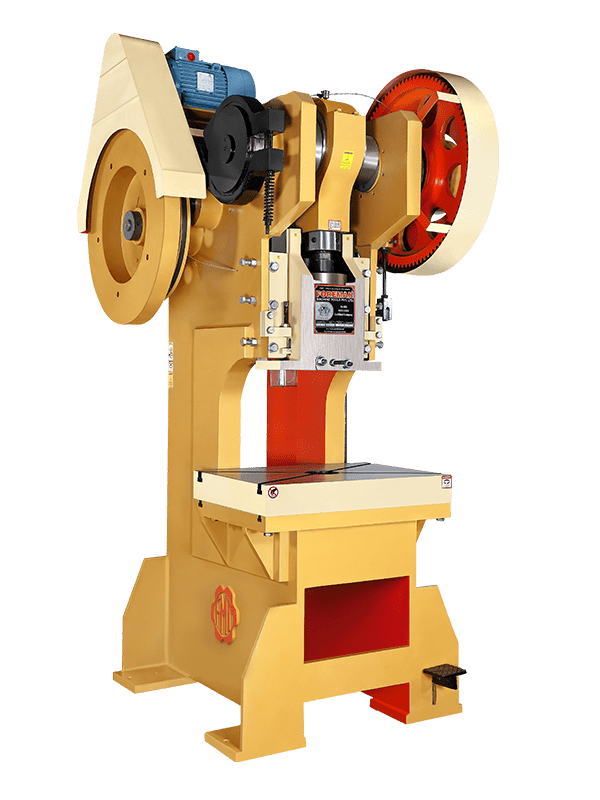

FMT ® Brand Heavy Duty mechanical Power Press is coming in “C” frame versions from 5 tons to 200 tons capacity in the most economical type of construction with several std./optional features such as manual/auto lubrication systems, knockouts electronics safety, Single/Double or Ungeared versions as also Pneumatic feeders/straightness & die-coilers for automatic Purposes.

Standard Accessories

- Motor pulley

- Slide Adj.Spanner

- Fly wheel & Gear guard

- Oil cups for lubrication point

- Knock-out system

Optional Accessories for C Type Power Press

- Tow hand operated clutch

- Extra base plate

- Inclinable Type

- Electric Motor, Starter and V-belts

- Single / continuous stroke

- Automatic lubrication pump

| Model No. | FMC-05 | FMC-10 | FMC-20 | FMC-30 | FMC-40 | FMC-50 | FMC-60 | FMC-80 | FMC-100 | FMC-150 | FMC-200 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CAPACITY IN TONS | 5 | 10 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | 150 | 200 | |

| Crankshaft Diameter | MM | 85 | 105 | 123 | 140 | 145 | 160 | 170 | 190 | 196 | 220 | 230 |

| Adj. Stroke Length | MM | 38 | 50 | 63 | 76 | 76 | 89 | 101 | 114 | 127 | 152 | 152 |

| Adjustment of Ram | MM | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Ram Face Size | MM | 190 x 100 | 240 x 114 | 292 x 127 | 317 x 140 | 342 x 152 | 368 x 165 | 393 x 177 | 444 x 190 | 495 x 203 | 622 x 241 | 750 x 292 |

| Punch Hole in Ram | MM | 25 | 25 | 32 | 38 | 38 | 45 | 45 | 50 | 50 | 80 | 80 |

| Hole in Bed | MM | 63 | 76 | 82 | 89 | 95 | 101 | 115 | 130 | 150 | 200 | 225 |

| Bed Size (Left to Right x Front to Back) | MM | 355 x 178 | 432 x 228 | 534 x 305 | 585 x 355 | 635 x 355 | 685 x 406 | 712 x 457 | 736 x 508 | 890 x 610 | 1041 x 737 | 1092 x 812 |

| Bed Thickness | MM | 50 | 58 | 63 | 70 | 76 | 83 | 88 | 95 | 114 | 127 | 137 |

| Dist.between bed to Ram | MM | 177 | 204 | 250 | 292 | 320 | 355 | 380> | 380 | 406 | 457 | 482 |

| Stroke per minute | MM | 80 | 80 | 45 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 35 |

| H.P.Required | ||||||||||||

| For Geared(1440 RPM) | HP | 1 | 1.5 | 2 | 3 | 5 | 5 | 7.5 | 10 | 10 | 15 | 20 |

| For Ungeared(960 RPM) | HP | 1 | 2 | 3 | 5 | – | – | – | – | – | – | – |

| Floor To Top of Bed | MM | 700 | 725 | 800 | 800 | 850 | 850 | 900 | 900 | 900 | 900 | 900 |

| All Over Size LR x FB x H | MM | 700 x 600 x 1600 | 800 x 800 x 1900 | 1000 x 1000 x 2100 | 1000 x 1100 x 2200 | 1100 x 1200 x 2400 | 1200 x 1300 x 2500 | 1300 x 1350 x 2650 | 1500 x 1500 x 2750 | 1750 x 1750 x 2900 | 2050 x 2000 x 3300 | 2200 x 2150 x 3500 |

| Weight Approximate | Kg. | 350 | 600 | 1100 | 1400 | 1800 | 2400 | 2600 | 3400 | 4800 | 6500 | 9000 |

All Dimensions are in M.M.

Design , Dimensions & Particulars are subject to alterations without notification.