Capacities rated for M.S. of U.T.S. 45 kg/mm2& S.S. of U.T.S. 72 kg./mm2. The hydraulic Shearing Machine will not cut any thickness variation beyond the rated capacity for any length. Right, to change specifications, features, and accessories without notice reserved, Compliance with safety requirements as per local regulations is the responsibility of the user.

Optional Accessories

- NC Backguage

- Rear Sheet Supports

- Automatic contorl shearing

- Sheet rear stacking system

Optional For Extra Requirements

Choice of CNC Controllers for controlling functions like NC backguage, blade gap, rake angle, stroke Also integrates the machine with automated accessories for sheet feeding, gauging, conveying seperating, stracking etc.

Salient Features

- Rigid structure as per international standards

- Moving beam synchronised by differential cylinders

- Hardened rollers guide beam for constant blade gap

- Rake angle adjustable to suit thickness and material

- Blade gap adjusted with leavers for clean cuts

- Sheets clamped hydraulically before cut starts

- Shearing-clamping forces adjustable to suit job

- Squaring arm 600mm at right-helps distribute wear

- Front gauging with stops. scale on squaring arm

- Ramp on rear slides out cut sheets outside shear area

- Footswitch movable for operation from safe position

- Finger safety guard with clear view of lighted cutting area

- Both blades premium HCHCr, four usable edges

- Cutting length and position adjustable for shorter jobs

- Beam returns on releasing footswitch for smaller cuts

- Cutting area illuminated for clear view

- First two hold-downs spaced closer at both ends

- Squaring arm 1000mm at left with hardened lines

- Front operated powered backguage range 1000mm

- Hardened rods, recessed table for easy sheet feeding

- Sheet supporter 1000mm long help supports long plates

- Dependable global of hydraulics, electricals

- Efficient compact powerpack with minimum piping

- Electricals neatly wired-labelled for trouble shooting

| Model | Cutting Length MM | Normal Rake Angle (M.S.) | Maximum Rake Angle (M.S.) | Normal Rake Angle (S.S.) | Maximum Rake Angle (S.S.) | Variable Rake Angle | Stroke/ Minute Min & Max Rake Angle | Hold Downs | Popwer H.P. | Packing Dimension In MM | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length A | Width B | Height C | ||||||||||

| HVR-315 | 1500 | 3 | 4 | 2 | 3 | 0.5-3° | 26/13 | 9 | 5 | 2250 | 1850 | 1950 |

| HVR-320 | 2000 | 3 | 4 | 2 | 3 | 0.5-3° | 24/12 | 11 | 5 | 2750 | 1850 | 1950 |

| HVR-325 | 2500 | 3 | 4 | 2 | 3 | 0.5-3° | 22/11 | 13 | 5 | 3200 | 1850 | 1950 |

| HVR-330 | 3000 | 3 | 4 | 2 | 3 | 0.5-3° | 20/10 | 17 | 7.5 | 3700 | 1850 | 1950 |

| HVR-415 | 1500 | 4 | 6 | 3 | 4 | 0.5-3° | 30/15 | 9 | 5 | 2250 | 1850 | 1950 |

| HVR-420 | 2000 | 4 | 6 | 3 | 4 | 0.5-3° | 27/12 | 11 | 7.5 | 2750 | 1850 | 1950 |

| HVR-425 | 2500 | 4 | 6 | 3 | 4 | 0.5-3° | 26/10 | 13 | 7.5 | 3300 | 1850 | 1950 |

| HVR-430 | 3000 | 4 | 6 | 3 | 4 | 0.5-3° | 25/10 | 17 | 7.5 | 3700 | 2250 | 2400 |

| HVR-440 | 4000 | 4 | 6 | 3 | 4 | 0.5-3° | 20/8 | 21 | 7.5 | 4700 | 2250 | 2400 |

| HVR-450 | 5000 | 4 | 6 | 3 | 4 | 0.5-3° | 15/6 | 25 | 10 | 5700 | 1900 | 2100 |

| HVR-460 | 6000 | 4 | 8 | 3 | 4 | 0.5-3° | 14/5 | 30 | 12.5 | 6700 | 1400 | 2100 |

| HVR-615 | 1500 | 6 | 8 | 4 | 6 | 0.5-3° | 20/10 | 9 | 7.5 | 2250 | 1900 | 2100 |

| HVR-620 | 2000 | 6 | 8 | 4 | 6 | 0.5-3° | 20/10 | 11 | 7.5 | 1750 | 1900 | 2100 |

| HVR-625 | 2500 | 6 | 8 | 4 | 6 | 0.5-3° | 25/11 | 13 | 10 | 3300 | 2250 | 2250 |

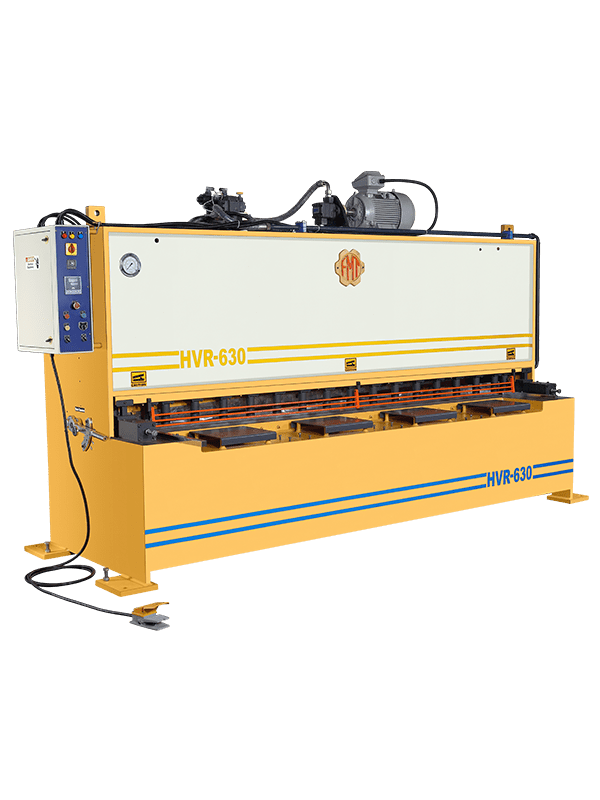

| HVR-630 | 3000 | 6 | 8 | 4 | 6 | 0.5-3° | 23/9 | 17 | 10 | 3800 | 2250 | 2500 |

| HVR-640 | 4000 | 6 | 8 | 4 | 6 | 0.5-3° | 20/8 | 21 | 12.5 | 4800 | 2500 | 2500 |

| HVR-650 | 5000 | 6 | 8 | 4 | 6 | 0.5-3° | 16/7 | 25 | 15 | 5800 | 2500 | 2700 |

| HVR-660 | 6000 | 6 | 8 | 4 | 6 | 0.5-3° | 12/5 | 30 | 20 | 6800 | 2700 | 2700 |

| HVR-815 | 1500 | 8 | 10 | 6 | 8 | 0.5-3° | 21/10 | 9 | 10 | 2250 | 2050 | 2200 |

| HVR-820 | 2000 | 8 | 10 | 6 | 8 | 0.5-3° | 17/8 | 11 | 10 | 2700 | 2050 | 2200 |

| HVR-825 | 2500 | 8 | 10 | 6 | 8 | 0.5-3° | 19/8 | 13 | 12.5 | 3300 | 2350 | 2600 |

| HVR-830 | 3000 | 8 | 10 | 6 | 8 | 0.5-3° | 17/7 | 17 | 15 | 3800 | 2350 | 2600 |

| HVR-840 | 4000 | 8 | 10 | 6 | 8 | 0.5-3° | 15/6 | 21 | 20 | 4800 | 2350 | 2600 |

| HVR-850 | 5000 | 8 | 10 | 6 | 8 | 0.5-3° | 14/5 | 25 | 20 | 5800 | 2500 | 2800 |

| HVR-860 | 6000 | 8 | 10 | 6 | 8 | 0.5-3° | 12/5 | 30 | 25 | 6800 | 2700 | 3000 |

| HVR-1015 | 1500 | 10 | 13 | 8 | 10 | 0.5-3° | 19/10 | 9 | 12.5 | 2250 | 2050 | 2300 |

| HVR-1020 | 2000 | 10 | 13 | 8 | 10 | 0.5-3° | 18/8 | 11 | 12.5 | 2750 | 2050 | 2300 |

| HVR-1025 | 2500 | 10 | 13 | 8 | 10 | 0.5-3° | 16/7 | 13 | 15 | 3300 | 2500 | 2800 |

| HVR-1030 | 3000 | 10 | 13 | 8 | 10 | 0.5-3° | 15/7 | 17 | 15 | 3800 | 2500 | 2800 |

| HVR-1040 | 4000 | 10 | 13 | 8 | 10 | 0.5-3° | 13/5 | 21 | 25 | 4800 | 2600 | 3000 |

| HVR-1050 | 5000 | 10 | 13 | 8 | 10 | 0.5-3° | 12/5 | 25 | 25 | 5800 | 2800 | 3000 |

| HVR-1060 | 6000 | 10 | 13 | 8 | 10 | 0.5-3° | 10/4 | 30 | 30 | 6800 | 3000 | 3200 |

| HVR-1315 | 1500 | 13 | 16 | 10 | 13 | 1-4° | 15/7 | 9 | 15 | 2300 | 2200 | 2500 |

| HVR-1320 | 2000 | 13 | 16 | 10 | 13 | 1-4° | 10/4 | 11 | 15 | 2800 | 2200 | 2500 |

| HVR-1325 | 2500 | 13 | 16 | 10 | 13 | 1-4° | 8/4 | 13 | 25 | 3350 | 2600 | 2800 |

| HVR-1330 | 3000 | 13 | 16 | 10 | 13 | 1-4° | 8/4 | 17 | 25 | 3850 | 2600 | 2800 |

| HVR-1340 | 4000 | 13 | 16 | 10 | 13 | 1-4° | 8/4 | 21 | 25 | 4850 | 2600 | 2800 |

| HVR-1350 | 5000 | 13 | 16 | 10 | 13 | 1-4° | 6/2 | 25 | 30 | 5850 | 2800 | 3000 |

| HVR-1360 | 6000 | 13 | 16 | 10 | 13 | 1-4° | 4/1 | 30 | 35 | 6850 | 3000 | 3200 |

| HVR-1615 | 1500 | 16 | 20 | 13 | 16 | 1-4° | 10/4 | 9 | 25 | 2350 | 2200 | 2600 |

| HVR-1620 | 2000 | 16 | 20 | 13 | 16 | 1-4° | 10/4 | 11 | 30 | 2850 | 2200 | 2600 |

| HVR-1625 | 2500 | 16 | 20 | 13 | 16 | 1-4° | 9/3 | 13 | 30 | 3350 | 2600 | 2900 |

| HVR-1630 | 3000 | 16 | 20 | 16 | 16 | 1-4° | 12/2 | 17 | 30 | 3900 | 2600 | 2900 |

| HVR-1640 | 4000 | 16 | 20 | 16 | 16 | 1-4° | 12/2 | 21 | 30 | 4900 | 2800 | 3000 |

| HVR-1650 | 5000 | 16 | 20 | 16 | 16 | 1-4° | 10/1 | 25 | 35 | 5900 | 3000 | 3200 |

| HVR-1660 | 6000 | 16 | 20 | 16 | 16 | 1-4° | 9/1 | 30 | 40 | 6900 | 3200 | 3400 |

| HVR-2015 | 1500 | 20 | 25 | 16 | 20 | 1-4° | 9/4 | 9 | 30 | 2350 | 2500 | 2600 |

| HVR-2020 | 2000 | 20 | 25 | 16 | 20 | 1-4° | 9/4 | 11 | 40 | 3900 | 2500 | 2600 |

| HVR-2025 | 2500 | 20 | 25 | 16 | 20 | 1-4° | 8/2 | 13 | 40 | 3500 | 2750 | 3000 |

| HVR-2030 | 3000 | 20 | 25 | 16 | 20 | 1-4° | 7/3 | 17 | 40 | 4000 | 2750 | 3000 |

| HVR-2040 | 4000 | 20 | 25 | 16 | 20 | 1-4° | 7/2 | 21 | 50 | 5000 | 2950 | 3200 |

| HVR-2050 | 5000 | 20 | 25 | 16 | 20 | 1-4° | 7/2 | 25 | 60 | 6000 | 3100 | 3400 |

| HVR-2060 | 6000 | 20 | 25 | 16 | 20 | 1-4° | 6/2 | 30 | 40 | 7000 | 3300 | 3600 |

| HVR-2515 | 1500 | 25 | 30 | 20 | 25 | 1-4° | 6/2 | 9 | 50 | 2400 | 2800 | 2800 |

| HVR-2520 | 2000 | 25 | 30 | 20 | 25 | 1-4° | 8/4 | 11 | 50 | 3100 | 2800 | 2800 |

| HVR-2525 | 2500 | 25 | 30 | 20 | 25 | 1-4° | 7/3 | 13 | 60 | 3600 | 2900 | 3000 |

| HVR-2530 | 3000 | 25 | 30 | 20 | 25 | 1-4° | 7/2 | 17 | 60 | 4100 | 3000 | 3200 |

| HVR-2540 | 4000 | 25 | 30 | 20 | 25 | 1-4° | 6/2 | 21 | 75 | 5100 | 3100 | 3200 |

| HVR-2550 | 5000 | 25 | 30 | 20 | 25 | 1-4° | 7/1 | 25 | 75 | 6100 | 3200 | 3500 |

| HVR-2560 | 6000 | 25 | 30 | 20 | 25 | 1-4° | 6/1 | 30 | 75 | 7100 | 3400 | 3700 |