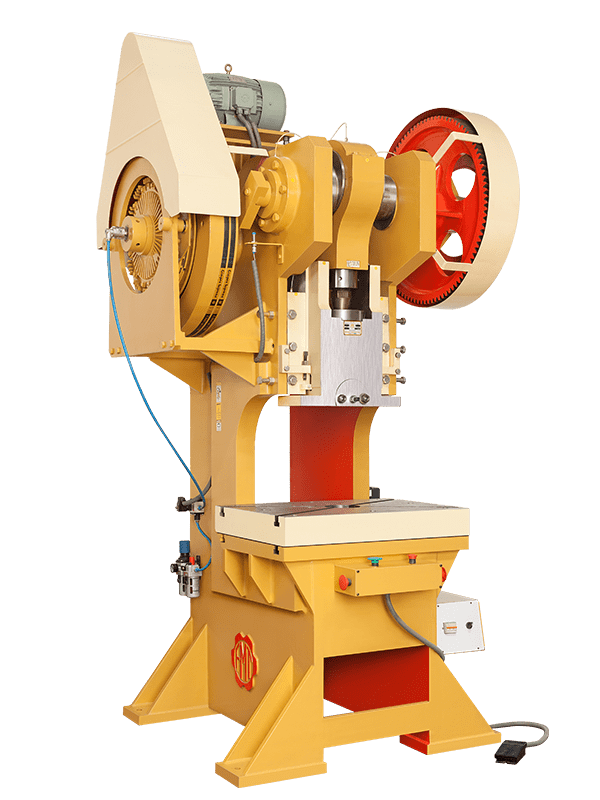

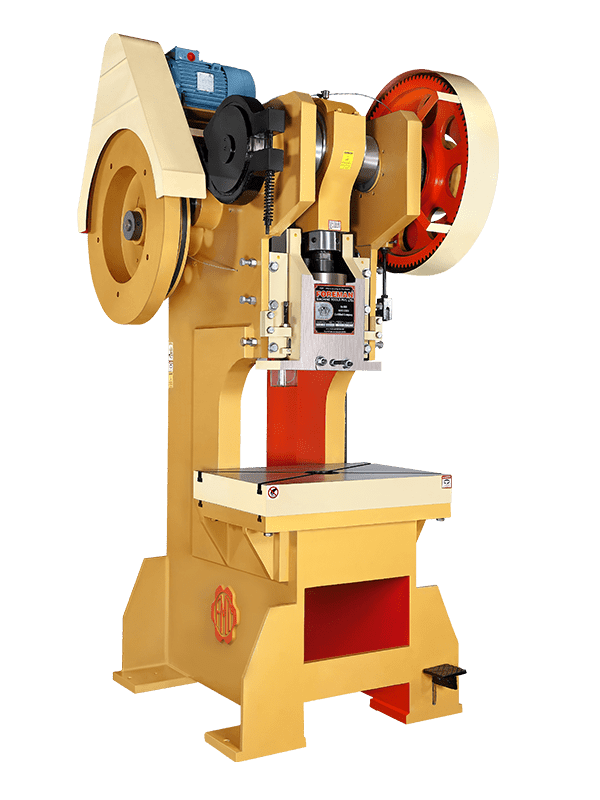

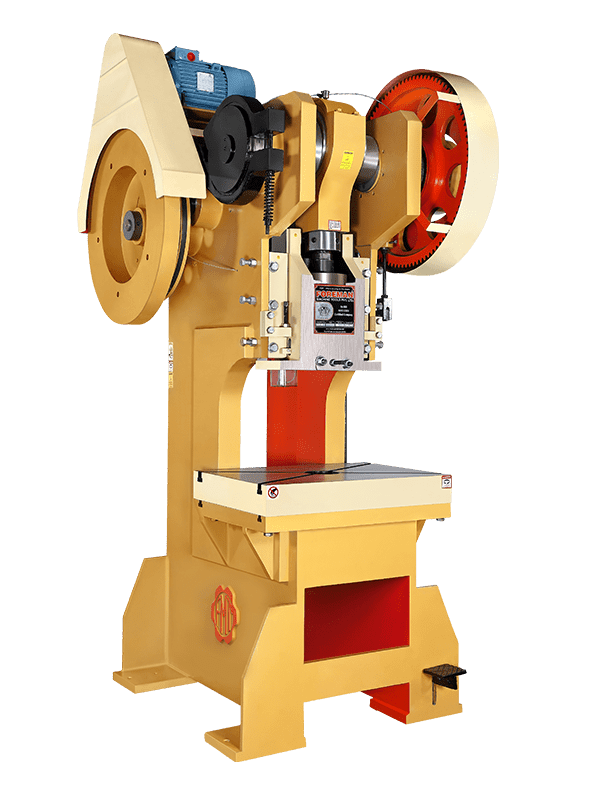

What is a C Type Power Press Machine? & It’s Application

September 20, 2021

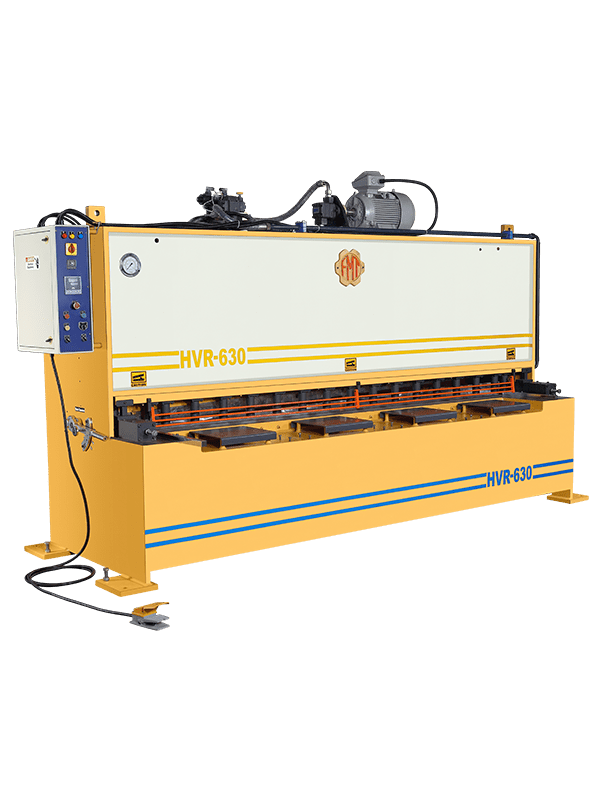

Hydraulic Shearing Machine

September 27, 2021Exploring the Power of Hydraulic Presses: A Comprehensive Guide

Hydraulic presses have been around for centuries and have been used in a wide range of industries. The public often overlooks and misunderstands these powerful machines. In this comprehensive guide, we will be exploring the power of hydraulic presses and their many applications. From the basics of how they work to the different types of presses available, you’ll gain a deep understanding of these impressive machines. But it’s not just about the technical details.

We’ll also dive into some of the most interesting and creative uses of hydraulic presses, from crushing everyday objects to creating intricate art pieces. Whether you’re a curious hobbyist or a professional in the manufacturing industry, this guide will provide you with the knowledge and inspiration to truly appreciate the power of hydraulic presses. So let’s get started and explore the world of hydraulic presses together!

Understanding the Basics of Hydraulic Presses

Hydraulic presses work by using hydraulic fluid to create force. The pump sends hydraulic fluid into a cylinder, which exerts force on a piston. The piston moves and transfers this motion to the press head. The press head allows customization for various types of force, like crushing, bending, or shaping. The force applied by the press depends on the amount of hydraulic fluid pumped into the cylinder. Pumping more hydraulic fluid generates a greater force.

Manufacturing commonly uses hydraulic presses for applying significant force to materials. The automotive industry utilizes them to shape metal parts. Hydraulic presses also find application in the aerospace industry for shaping materials used in aircraft.

One advantage of hydraulic presses is that they can apply a great deal of force without the need for additional mechanical components. This means that hydraulic presses can be more compact than other types of presses, making them ideal for use in smaller spaces.

Advantages of Hydraulic Presses

Hydraulic presses have many advantages over other types of presses. One advantage is that they can apply a great deal of force without the need for additional mechanical components. This makes hydraulic presses more compact and easier to use than other types of presses. Furthermore, you can customize hydraulic presses to apply various forces, including crushing, bending, or shaping.

Another advantage of hydraulic presses is that they are energy-efficient. Unlike other types of presses that rely on electricity or other energy sources, hydraulic presses only require hydraulic fluid to generate force. This makes hydraulic presses more cost-effective to operate, as they require less energy to operate.

Hydraulic presses are also more reliable than other types of presses. This is because hydraulic fluid is incompressible, which means that the force generated by the press is consistent. Additionally, hydraulic presses are less likely to break down than other types of presses, as they have fewer moving parts.

Applications of Hydraulic Presses

Hydraulic presses have numerous applications in various industries. Some of the most common applications of hydraulic presses include:

Metalworking

Metalworkers commonly use hydraulic presses for bending, shaping, and stamping metal parts, as these presses exert significant force to shape and form them.

Plastic Moulding

Hydraulic presses find application in plastic moulding, shaping plastic parts into the desired form. Injection moulding commonly utilizes hydraulic presses to inject plastic into a mould and shape it.

Woodworking

Woodworking applications commonly use hydraulic presses for bending and shaping wood parts. Hydraulic presses exert significant force on wood, enabling the desired shaping and forming.

Crushing Objects

Hydraulic presses are also used for crushing objects. This is a popular application of hydraulic presses, and there are many videos online of hydraulic presses crushing various objects, such as phones, toys, and even bowling balls.

Factors to Consider When Choosing a Hydraulic Press

When choosing a hydraulic press, there are several factors that you should consider. These factors include:

Force Capacity

The force capacity of a hydraulic press is one of the most important factors to consider. The force capacity is the amount of force that the press can apply. You should choose a press with a force capacity that is appropriate for your application.

Bed Size

The bed size of a hydraulic press is another important factor to consider. The bed size is the size of the area where the material is placed. You should choose a press with a bed size that is appropriate for your application.

Type of Force

The type of force that the press can apply is also an important factor to consider. Choose a press designed for the specific force you require, be it crushing, bending, or shaping.

Speed

The speed of the press is also an important factor to consider. The speed is the rate at which the press applies force. You should choose a press with a speed that is appropriate for your application.

Maintenance and Safety Tips for Hydraulic Presses

Maintaining hydraulic presses is important to ensure that they operate efficiently and safely. Some maintenance and safety tips for hydraulic presses include:

- Regular Inspection: Regularly inspect the hydraulic press to ensure that it is in good working condition. Look for any signs of wear and tear, leaks, or other issues that may affect the performance of the press.

- Lubrication: Lubricate the press regularly to ensure that it operates smoothly. Use the appropriate lubricant for the type of press that you have.

- Safety Measures: Always follow safety measures when operating a hydraulic press. Wear appropriate personal protective equipment, such as gloves and eye protection. Ensure proper grounding of the press and place all safety guards appropriately.

Frequently Asked Questions about Hydraulic Presses

Q: What is a hydraulic press used for?

A: Hydraulic presses are used for a wide range of applications, including metalworking, plastic moulding, and woodworking. They are also used for crushing objects.

Q: How does a hydraulic press work?

A: Hydraulic presses work by using hydraulic fluid to generate force. A pump forces hydraulic fluid into a cylinder, which applies force to a piston. The piston moves and transfers this motion to the press head.

Q: What are the advantages of using a hydraulic press?

A: Hydraulic presses are more compact, energy-efficient, and reliable than other types of presses. They can also be customized to apply different types of force.

Conclusion

Hydraulic presses are powerful machines that have been used in various industries for centuries. They are more compact, energy-efficient, and reliable than other types of presses. Hydraulic presses come in different types, each with its own unique features and applications. When choosing a hydraulic press, it’s important to consider factors such as force capacity, bed size, and type of force. Maintaining and following safety measures when using hydraulic presses is important to ensure their longevity and safe operation.

Read More: What is a C Type Power Press Machine? & It’s Application

For more information, Contact Us.