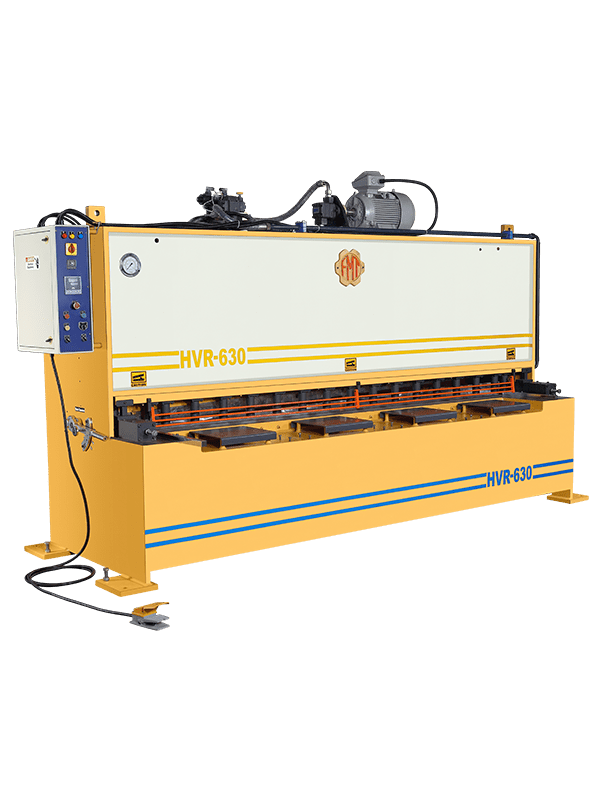

Hydraulic Shearing Machine

September 27, 2021

What is a pneumatic power press? Advantages & Disadvantages Of Pneumatic power press

October 4, 2021What is a Press Brake?

A press brake is a piece of production equipment that is utilized to bend sheet metal. A press brake is regularly narrow and long so that a big piece of sheet metal can be bent by it. A press brake bends sheet metal by bringing down a punch onto sheet metal that has been situated on top of a die. The metal might be bent a few times by a press brake until the ideal structure has been accomplished.

Types of press brakes

There are different types of press brakes like…

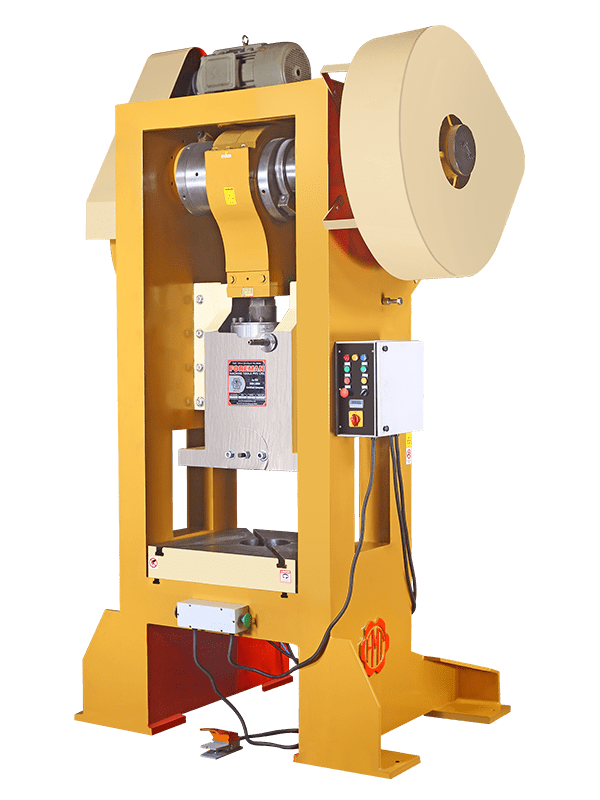

Mechanical press brakes

Mechanical press brakes work via a machine inside the device. This machine produces a large flywheel at a high rate. The machine operator controls the flywheel through a clutch, which then sets the remainder of the parts into a movement to turn the metal.

Electric press brakes

Electric press brakes are more uncommon than water-powered press brakes as they are newer to the scene. Still, they offer many features not found in hydraulic brakes. Being totally electronic, there is no requirement for hydraulic oil and therefore no oil drops.

Operating charges are additionally decreased as energy needs are lower because engines are not continuously run. Electric brakes tend to be more accurate, faster, and smaller in size coming in less than 60 tons.

Hydraulic press brakes

Hydraulic press brakes, as well as their pneumatic partners, are also generally utilized and can be more suited to heavy-duty responsibilities, while also offering greater levels of safety.

Read More: Hydraulic Shearing Machine

Application of press brake machine

- Automotive boards

- Airframes

- Metal artwork

- Furniture

- Metal containers