What is a pneumatic power press? Advantages & Disadvantages Of Pneumatic power press

October 4, 2021

What Is A Punching Press? & It’s Parameters

October 11, 2021Mechanical Press

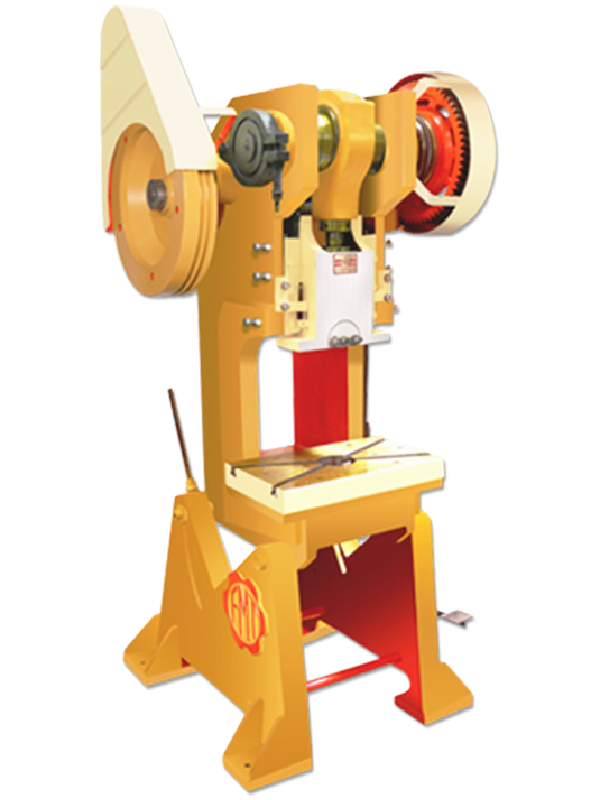

A mechanical press is a machine that’s used for forming manufacturing sheet metal and metal extrusion. Press machines are the perfect and normal machine tools that can be separated into a hydraulic press and mechanical press.

The press working is an essential recent metal invention method across industries. The mechanical press isn’t just utilized for sheet metals but also utilized for manufacturing plastic items and a variety of machining tasks, such as broaching.

Machine Power Press Manufacturers including mechanical press and hydraulic press all require lots of power to complete the metalwork, for example, to damage a significant piece of metal. Variety of power sources, the manner and nature where the machine press will transfer the energy vary, determine the efficiency as well as the output the machine tool can provide.

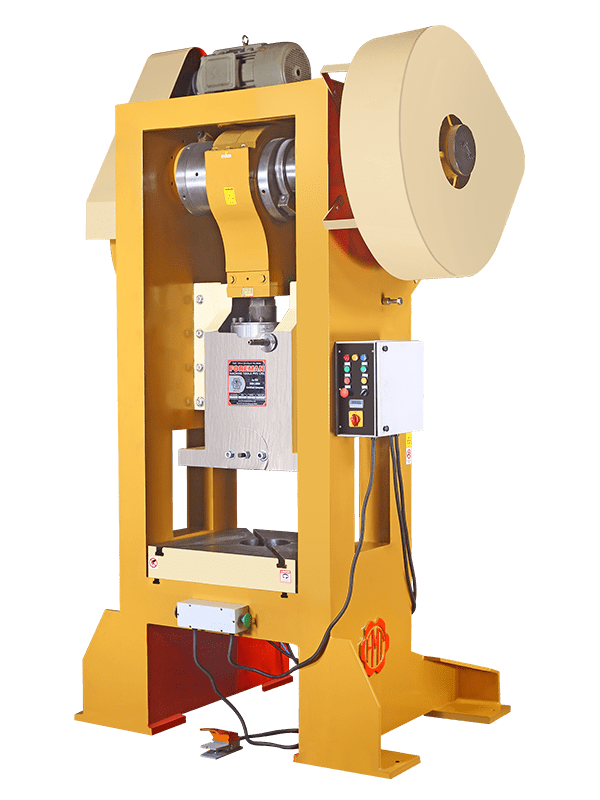

In a vertical mechanical press machine, the power vector works higher and down relative to gravity.

In different cases, the equal machine type is mounted horizontally where the working force is applied to the path perpendicular to the direction of gravity. The working principle of the mechanical press is however the same no matter whether the power is applied vertically, horizontally or at the central point.

Read More: What is a pneumatic power press? Advantages & Disadvantages Of Pneumatic power press

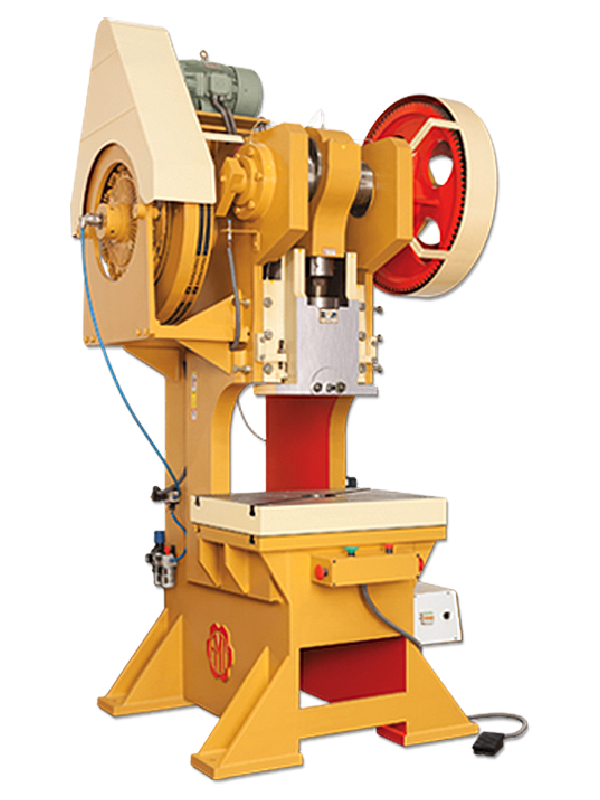

Works Of Mechanical Press:

The working principle of the mechanical press is to change the rotational power from the electric motor to a translational power which drives the mechanism of pressing work. The energy wellspring of the mechanical press machine is typically a motor. Utilizing a mechanical press machine, there are 3 fundamental stages to finish the metal forming process.

The production cycle starts with the material set on the dies where the metal sheet or other crude materials should stay in place for machining. The operators should then control the mechanical press to apply proper pressure in order to power and shape or adjust the crude materials as they need. Therefore, the finished products will be ejected and gathered from the mechanical machines.

All parts in a mechanical press need to be greased up through the inward system, in general, which supplies a stable flow of oils to guarantee smooth development during the pressing process.

Mechanical presses are high machine tools that may be risky somewhat. The activities require laborers with appropriate preparation and safety procedures.