What Is A Advantages Of Hydraulic Presses

October 18, 2021

Advantages of Hydraulic Shearing Machine

October 25, 2021Punch press

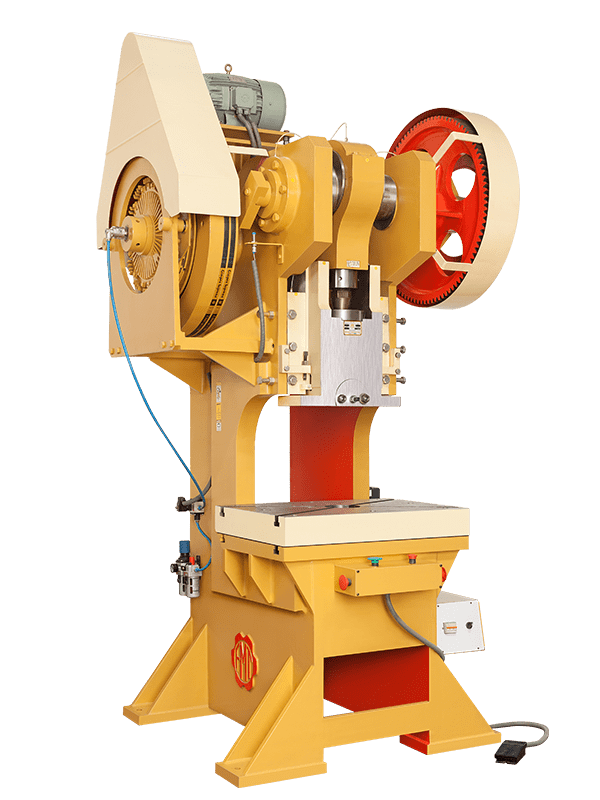

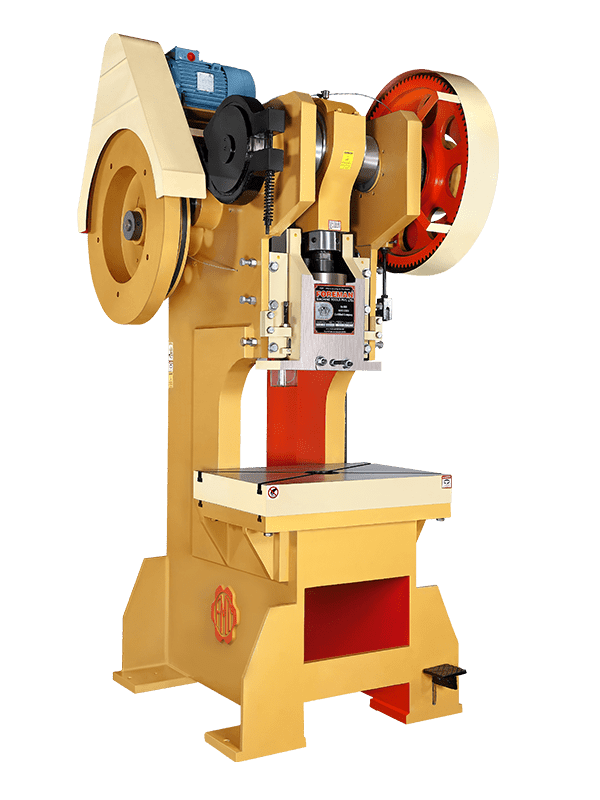

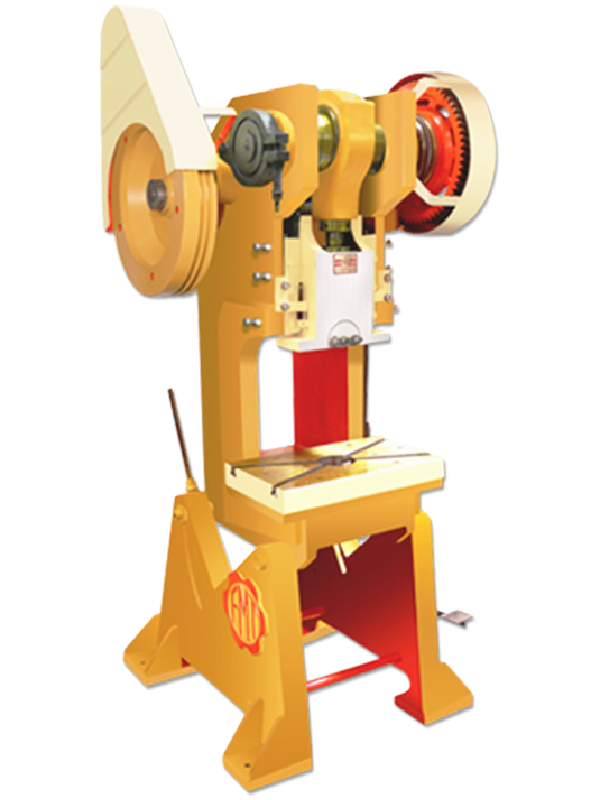

A CNC punch press is a metal fabrication apparatus utilized to process flat blank sheet metal. The punch press consists of a large turret that can hold over 70 various punches and colors. These punches and colors are constrained by a computer and can be utilized to make a wide range of various shapes and provisions.

Punch presses can complement CNC lasers, or work as savvy electives.

Punch presses can create features like counterbores and counter adjusts that are formed solidly into the material, or expulsion decorates and pivots that protrude from the material. Adding these features into your parts can save you much cash over the long run by reducing the requirement for secondary operations. Explore Pneumatic Power Press

Advantages:

Utilizing compacted air as the power source, proficient and easily operate simple construction, and minimal maintenance.

Less sound than traditional power press, It can save power use and decrease manufacturing cost.

Adjustable height, speed, stroke, pressure, and stamping time according to different products or mold.

punching machines can accomplish geometrically precise shapes to the most significant levels of value – with no needle holes or scatter, no waves or scratches. for example, that you can create an excellently round circle or a perfect square.

In case you are producing various indistinguishable shapes in one go, punching is unbearably fast and has no contest when it comes to price. Punctured sheets are a classic processing example: for this application, punching machines outflank all other technologies in terms of speed and cost-effectiveness.

Equipped with an anti-rotation guide bar, a guide plate, high accuracy, can adjust to high-speed accuracy blanking.

The structure is simple and accepts pneumatic innovation so that compressors can be utilized for the work of different pneumatic punching machines, which can be more energy-saving than the electric punch.

Read More: What is a Advantages of Hydraulic Presses