Advantages of Hydraulic Shearing Machine

October 25, 2021

What is Press Brake? How does the press brake work?

November 1, 2021Types

Various types of Shearing machine is available in the growing market

Hydraulic Shearing Machine

The hydraulic swing beam shearing machine has a steel welded development, hydraulic transmission, and accumulator stroke back. This effective machine is easy to operate. The indicators for changing the gap between blades help to rapidly, conveniently align shadow light.

The top blade gap can be adjusted for full stroke, while shorter ones help to safeguard clients. It has a digital display that demonstrates the stock situation of the back gauge and shearing count.

The machine also allows spindle allowance, and has a stock counter, web time relay, inch-mm selector; and the essential factor can be easily customized.

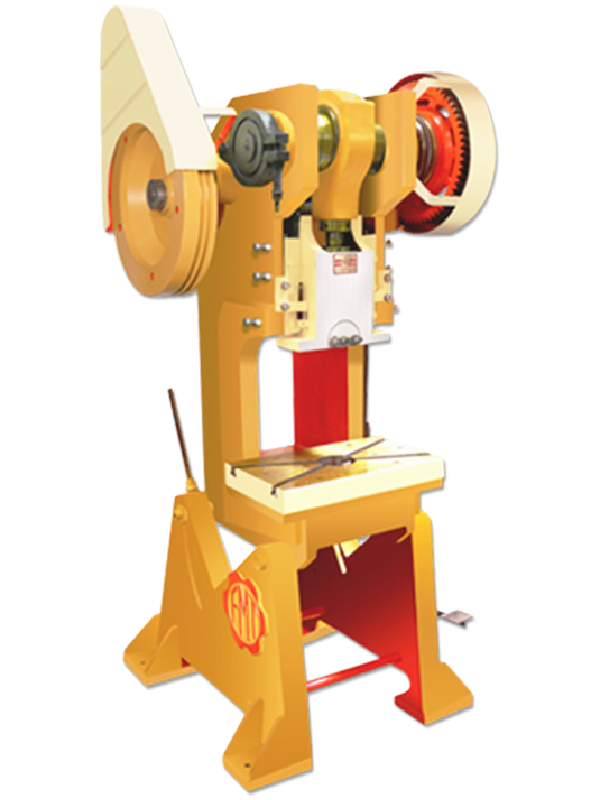

Another type is the hydraulic shearing machine, which has a robust, stress-safe steel welded structure. The hydraulic driven blade holder can be removed by the cylinder accumulator.

Moreover, the rake angle and back gauge travel can be adjusted utilizing fine handles to decrease the deformation of the sheared plate. It has a digital counter that shows the cutting time and a swing-away back gauge for cutting long sheets. The pointer helps to effectively, quickly adjust the clearance of four edge cutting blades.

The full-short stroke of the blade holder is also flexible. It even incorporates a three-guide streetcar that moves precisely to provide superior shearing. The front, preloading rail structure powers the blade holder to continuously move along the upper and lower rail without the gap. Further, the blade gap is movable for different plates to get better shearing.

Read More: Advantages of Hydraulic Shearing Machine

Bench shear

The word bench is because the machine is mounted on a bench to build its mechanical capacity. It is utilized to cut rough shapes of medium sizes of metal. However, small bench shearing machines are fitted with ground cutting blades and are lightweights making it simple to have spotless and quick cuts.

Guillotine

This implies that the machine is hand or foot-powered and sometimes precisely controlled. The material to be cut is first confined with a ram and a moving blade goes down and shears the metal. A power shearing machine comprises a shear table to put the material being sheared, a holding device to hold the material set up to avoid movement, a measuring device to ensure the material is in the right place, and the lower and upper sharp blades to do the cutting.