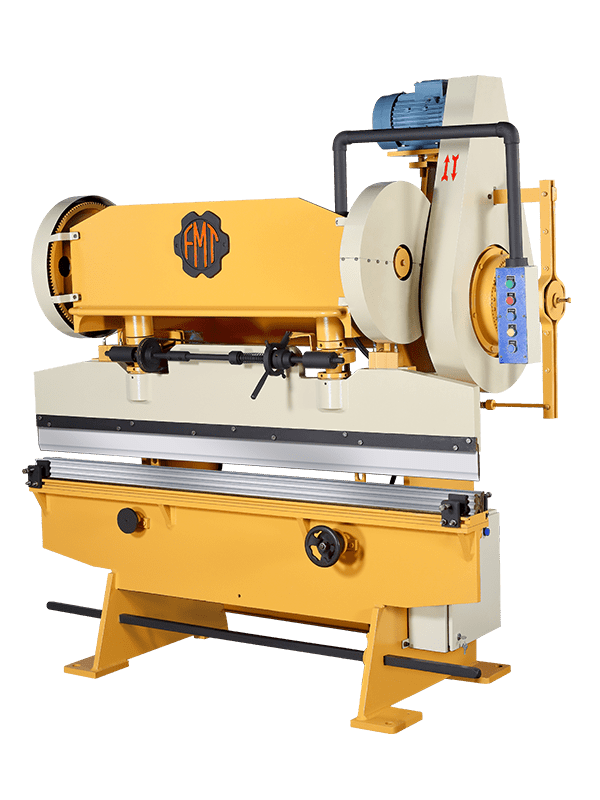

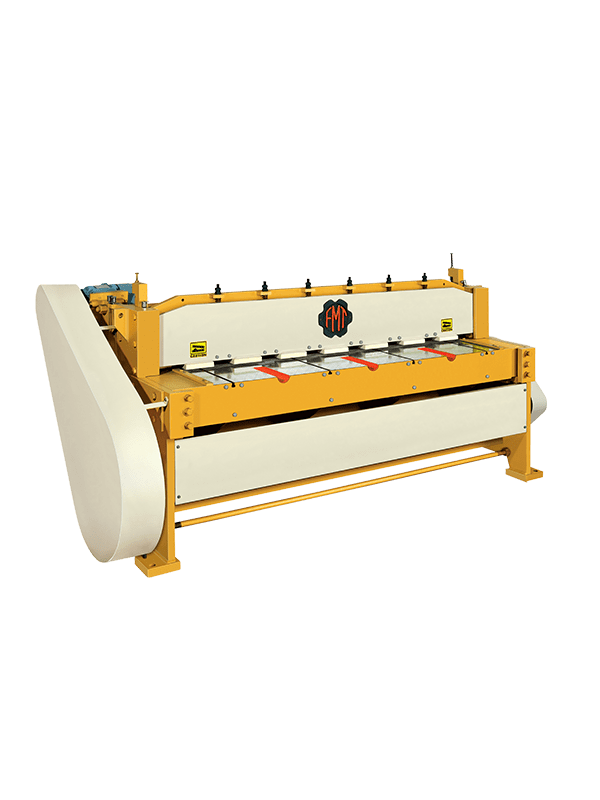

Under Crank Shearing

November 10, 2021

Various types of Machine Presses

November 17, 2021When you’re taking a glance at a press brake, it’s essential to know what sort of press brake you’re managing. Various machines will put force on an item in various techniques -which means that they have various components which will require distinctive maintenance techniques.

Depending on how they apply force to a product, there are four particular sorts of press brakes:

Mechanical

The most established kind of press brake machine. This variation would utilize a flywheel fueled by an electric engine to supply the power for twisting materials. Quick and exact, yet was generally superseded by hydraulic presses on the grounds that, as indicated by The Fabricator, accuracy work will take a skilled worker, additional arrangement pieces, and a ton of creation time.

Pneumatic

These press brakes use pneumatic force to move their ram’s top and bottom. These machines are like hydraulic presses, however, they for the most part have a much lower weight limit.

Hydraulic

Hydraulic liquids contained in at least one chamber are utilized to constrain the smash of the press brake down onto the workpiece being shaped – instead through a few models to move the bed up. Hydraulic-powered controls are for the most part more exact than mechanical ones and can be adapted to individual bend depth.

Servo-Electric

Servo-electric press brakes utilize an electric engine to drive the movement of the smash. While exceptionally quick and effective contrasted with other press brake innovations, they are restricted to low-weight work. One advantage of these machines, as indicated in another article, is that Having no hydraulic oil or related seals works on support.

Read more about: Under Crank Shearing

When discussing press brakes, individuals are by and large contemplating either the mechanical or the hydraulic-powered drive frameworks, as these are the most normally known. The choice on which kind of press brake you should utilize will rely upon your application. You have a ton of framing to do that doesn’t require high weights, a servo-electric machine may work for you. If you want to twist exceptionally thick bits of steel, a hydraulic machine may be better.