All About Press Brakes

November 22, 2021

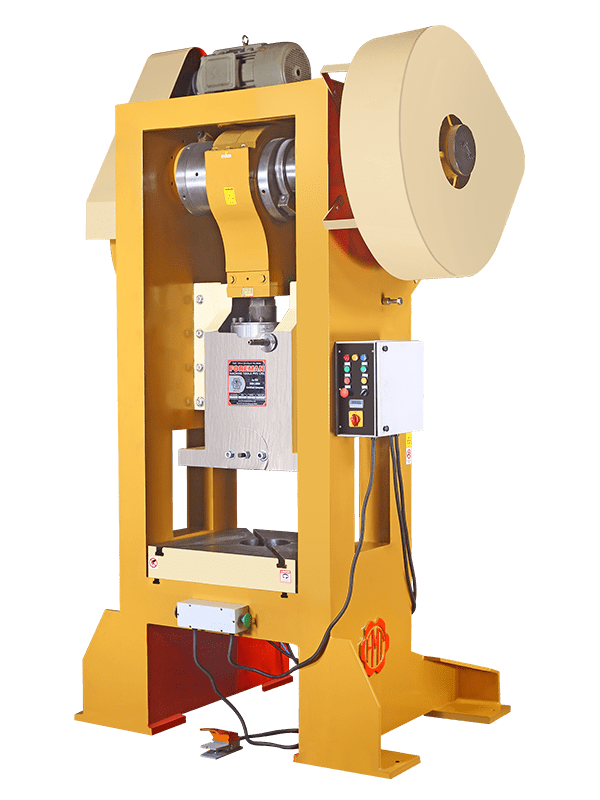

How Pneumatic Press is Utilized in Production, Manufacturing

November 29, 2021Step by step instructions to utilize a Hydraulic Press

This is an article on the basics of utilizing the Foreman Machine Tools Manual Hydraulic Press Brake. It is sometimes utilized for KBr pellet planning, XRF sample preparation, and FTIR pellet pressing, alongside different applications.

Essential guide: How to utilize a Manual Hydraulic Press

1. Raise the front safety guard, put down the work to be pressurized midway on the lower bolster squeezing face, and bring down the safety guard.

The safety guard should be kept close consistently when work is being pressurized. You might have to pivot the strain release handle clockwise until it has fixed solidly, to close the pumping framework prior to developing tension. You will actually want to align your weight limit utilizing this release handle.

2. Lower top bolsters pressurized face, by turning the lead screw handle clockwise.

It is significant that you guarantee every one of the parts of the work to be pressurized has been crushed firmly together prior to beginning to pump a strain. Notwithstanding, leave a 1 mm hole between the highest point of the work and the top support pressurized surface. To consider some underlying travel of the squeezing piston.

3. Pull and push the pump for managing developed pressure flawlessly.

When the work inside the press opposes the pump pressure, the load will be demonstrated on the gauge. Proceed until the required load is accomplished on the measure. Be sure that the safety guard is completely brought down prior to pumping. The right influence and power might be applied by holding the pump handle at its elastic grasp.

Read more: Various types of Machine Presses

It should just take a couple of strokes to develop tension in the pressure-driven oil of the manual press. There is the highest piston-cylinder travel of 26 mm. There is a red ring around the cylinder showing when the cutoff has been reached. Try not to keep pumping when this red ring shows. Otherwise, you could make harm to the press system.

4. To release the strain load, turn the tension delivery handle anticlockwise by one turn.

The pressure and applied weight load against the work will be held however long needed. You might notice a slight reduction in the strain applied, shown at the load check, as the work being pressurized relaxes over the long run. You can bring the pressed back up to the needed load whenever wanted, by pulling delicately on the top of the pump.

Turn the top of the lead screw anticlockwise to raise the squeezing face, open the front safety guard and eliminate the work internal.

There is no requirement to turn this handle totally open. Turning this lead screw drops the tension of oil inside the manual pressure-driven press and depletes the oil once more into the supply.