How do you Utilize a Hydraulic Press?

November 24, 2021

The Most Important Things You Should Know About Press Brakes

December 2, 2021Multipurpose press and assembling machine set up in a work environment

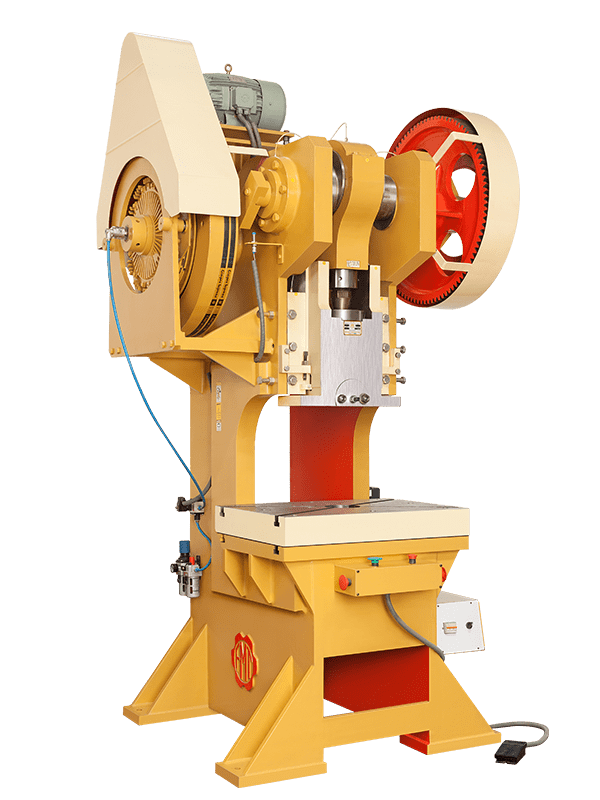

Producing organizations usually utilize hard-core industrial machines to break the metal workpieces, one of which is a Pneumatic Press. Like different presses, it’s equipped for performing a huge range of manufacturing processes. The pneumatic press can cut, punch, twist, draw and structure workpieces. If you’re unusual to them, however, you may be considering how pneumatic presses are utilized in production and manufacturing.

What Is a Pneumatic Press?

A pneumatic press is a kind of forming press that utilizes a pneumatic situation to control a workpiece through the previously mentioned producing processes. They ordinarily highlight a rectangular casing. After placing the workpiece in the casing, the highest point of the pneumatic press drops down to control it.

Pneumatic press work by putting pressure on the workpiece. When a workpiece is set in a pneumatic press, it will be reduced to pressure. The head of the pneumatic press will push down onto the metal workpiece. Because of the strain behind it, the pneumatic press will then control the workpiece.

Advantages of utilizing pneumatic presses in manufacturing the accompanying:

Supports workpieces in various materials

Low energy utilization

Doesn’t deliver heat

Cost-efficient for large scale manufacturing processes

Produces negligible noise during activity

Offers command over the workpiece’s size

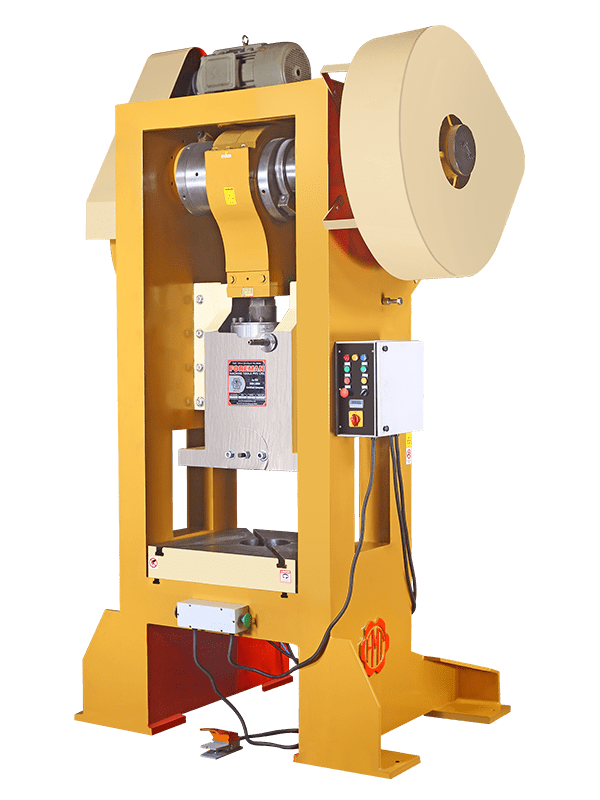

Pneumatic Press versus Hydraulic Press

Some shaping presses utilize a hydraulic power system to control workpieces. Known as hydraulic presses, they are fit for performing large numbers of similar manufacturing processes as their pneumatic counterparts. Hydraulic and pneumatic presses aren’t similar.

Hydraulic presses are controlled by a compressed fluid. They include a cylinder that drops down into a fluid-filled storage tank. As the cylinder presses into the fluid-filled storage tank, it generates strain on the top plate, pushing the top plate into the workpiece. The fluid can’t grow inside the fixed storage tank, so it generates pressure because of the cylinder.

Read more: How do you Utilize a Hydraulic Press?

A pneumatic presses, on the other side, are mechanized by compressed gas or air. They highlight a chamber that is loaded up with compressed gas or air. Like hydraulic presses, pneumatic presses influence compressive powers to control workpieces. The difference is that hydraulic presses utilize compressed fluid, though pneumatic presses utilize compressed gas or air. When contrasted with hydraulic powered presses, pneumatic presses are quicker and simpler to manage.