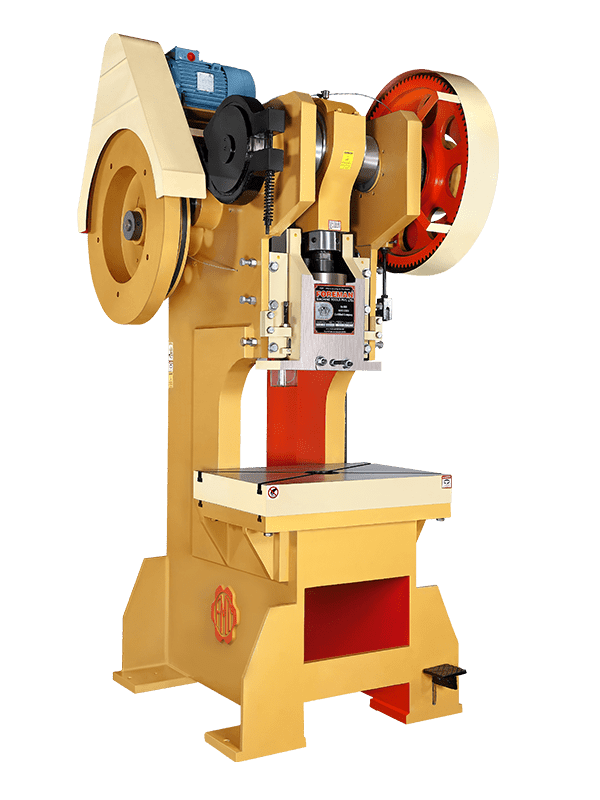

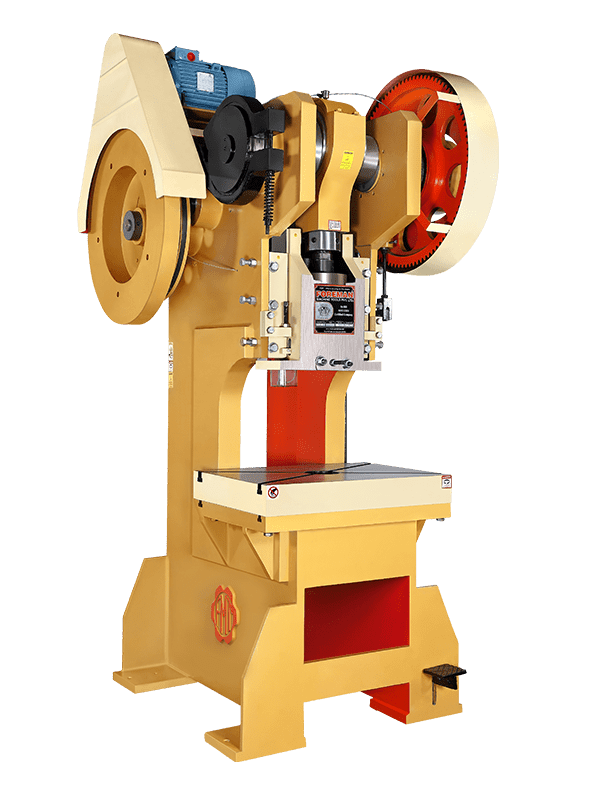

Power Press Machine Manufacturers

June 10, 2023

Hydraulic C Type Power Press

July 29, 2023Press Brake Machine Manufacturers

Foreman Machine Tools Pvt. Ltd. is one of the famous Press Brake Machine Manufacturers in India. In the realm of industrial manufacturing, press brake machines have become indispensable tools for shaping and bending various types of sheet metal. These powerful machines offer a multitude of benefits and find extensive usage across diverse industries. Here, we will delve into the needs, benefits, and versatile usage of press brake machines, highlighting their significance in modern manufacturing processes.

We are making Two types of Press Brake Machines,

Meeting Industry Needs

- Flexibility and Versatility: Press brake machines are designed to cater to a wide range of bending requirements, making them suitable for various industries such as automotive, aerospace, construction, and more. They can handle different materials, thicknesses, and shapes, providing unparalleled flexibility in metal fabrication.

- Precision and Accuracy: With advanced technology and precision engineering, press brake machines ensure consistent and accurate bending operations. They offer precise control over angles, dimensions, and depths, allowing manufacturers to achieve high-quality results and meet tight tolerances.

Benefits of Press Brake Machines

Increased Productivity: Press brake machines enhance productivity by automating the bending process. These machines feature programmable controls, allowing operators to store and recall bending sequences, reducing setup time and minimizing errors. Faster cycle times and high production rates help meet deadlines and fulfil large-scale manufacturing requirements.

Cost-Efficiency: By streamlining operations and minimizing material waste, press brake machines contribute to cost savings. The ability to bend complex shapes in a single setup reduces the need for additional tooling and secondary operations. Moreover, precise bending minimizes material distortion and reduces scrap, optimizing material utilization.

Improved Safety: Modern press brake machines incorporate safety features such as guards, sensors, and interlocks to protect operators from accidents. Emergency stop buttons and safety light curtains ensure a safe working environment, minimizing the risk of injuries and enhancing workplace safety compliance.

Versatile Usage of Press Brake Machines

Prototyping and Customization: Press brake machines allow manufacturers to create prototypes and customize products according to specific requirements. The ability to produce complex shapes and intricate bends enables the production of unique and tailor-made components.

Metal Forming: Press brake machines excel in metal forming processes, enabling the creation of curved, folded, or angled metal parts. From simple brackets to complex architectural structures, these machines offer the versatility needed to meet diverse metal forming needs.

Batch Production: Press brake machines are ideal for batch production, allowing manufacturers to efficiently produce a large quantity of consistent and high-quality parts. By automating repetitive bending tasks, these machines ensure uniformity and optimize production cycles.

Conclusion

Press brake machines have become vital assets in modern industries, fulfilling the needs of precision metal bending and fabrication. With their flexibility, precision, and efficiency, these machines boost productivity, reduce costs, and enable customization. Whether it’s prototyping, metal forming, or batch production, press brake machines have revolutionized manufacturing processes, setting new standards for quality and reliability. Embrace the power of press brake machines and unlock endless possibilities in your industrial operations today.

Read more: Power Press Machine Manufacturers

For more information, Contact Us.