What Is A Mechanical Press? How Does It’s work?

October 6, 2021

Types Of Presses

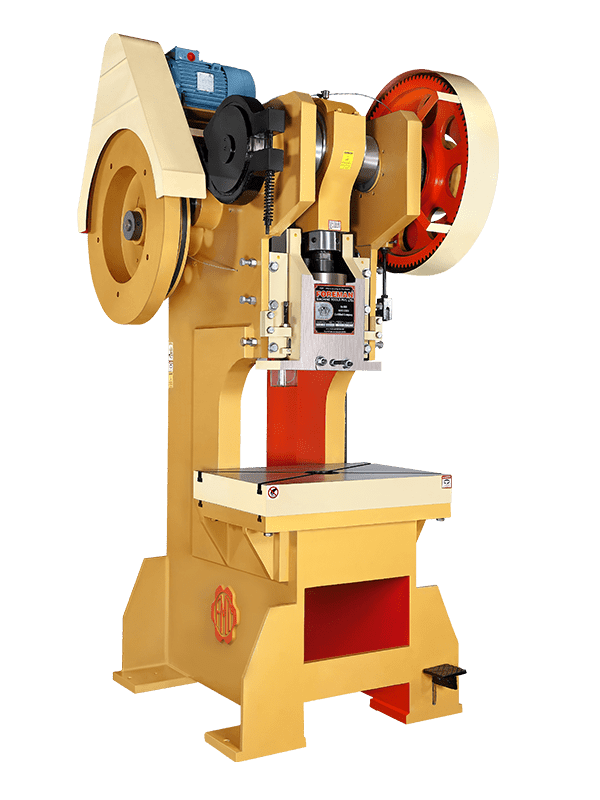

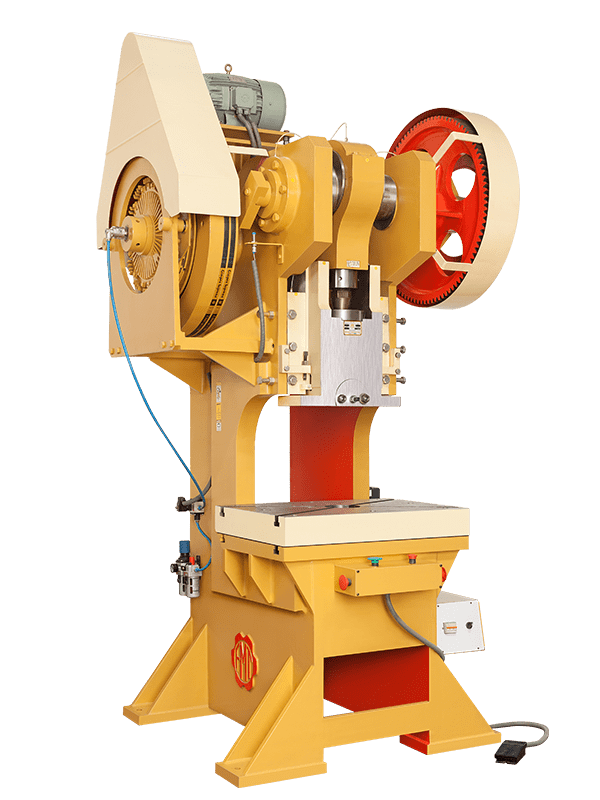

October 13, 2021What Is A Punching Press?

A punch press is one type of machine press utilized to cut holes in the material. It can be little and manually worked and hold one simple die set, bite the dust setting, or be exceptionally enormous, CNC operated, with a multi-station turret and hold a larger and complex die set.

Punch presses are large machines with either a ‘C’ type frame or a ‘gateway’ type frame. The C sort has the hydraulic ram at the top premier part, though the portal frame is much akin to a complete circle with the ram being centered inside the frame to stop frame turning or warping.

C-type power presses have a bedplate that is utilized to lock the die bottom bolster. For locking the die, T-bolts are utilized, thus this plate contains T-slots into which T-bolts are slid in. These slots are put cornerwise and with a slot parallel to the longer side of the plate.

These slots run up to a focal opening made in the plate, the hole being sufficient enough to accommodate one more shrub with a hole, the hole is utilized for dropping the punched part to the footer part of the press.

The head of the tool butted against an upward sliding ram with a clamping system that takes in only a specific diameter of a threaded valve member called the “shank” of the tool.

The bottom part of the tool is locked to the bottom bedplate and the top parts of the tool are locked to the sliding ram. The top and bottom parts of the tool are generally directed by appropriate pillar and bush assemblies, which give safety to the punching components of the tool.

The tool is put somewhat over the base bed plate by giving two equal squares precisely ground to a similar size. This is a fundamental activity since in many tools, scrap is released through the bottom component of the tool, not really in the center of the tool.

Read More: What Is A Mechanical Press? How Does It’s work?

The Punch Press Is Characterized By Parameters Likes..

- Frame type

- Instrument of delivering capacity to the ram

- Size of the working region

- Single or multiple-station

- Power rating

- The kind of hardware store and its ability

- Speed or productivity

- Speed of movement without shock

- Maximum weight of workpiece

- Security features

- Power utilization