What Is A Punching Press? & It’s Parameters

October 11, 2021

What Is A Advantages Of Hydraulic Presses

October 18, 2021Presses:

The presses are accessible in various designs and shapes, according to the work demands.

Types Of Presses

Manually Operated Press:

The press is worked by human hands. It is a bench-mounted press regularly utilized for the creation of small parts. It is a simple and minimal expense press, reasonable for light activities, such as puncturing, blanking, bowing, etc.

The arm is rotated manually, the ram is moved manually to perform the mandatory activity. The ram is fitted with a punch. The work is laying on the bed.

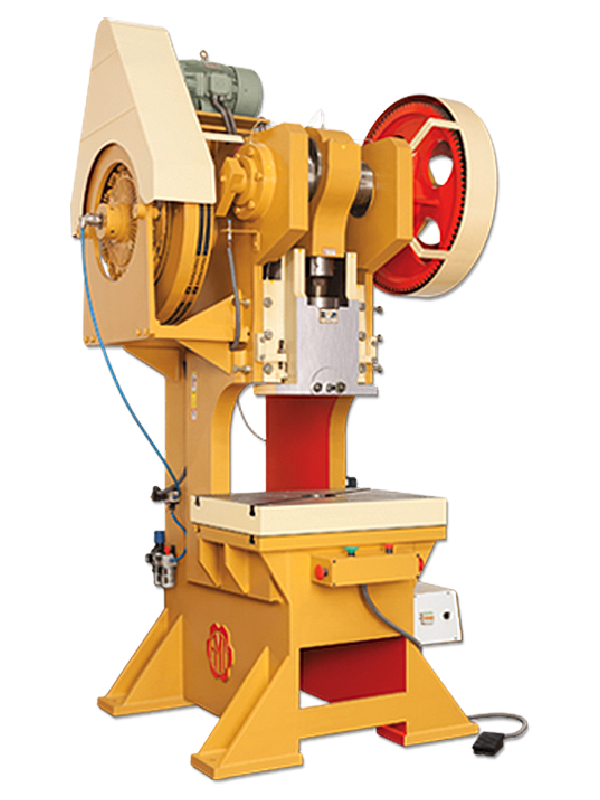

Electric Motor Operated Press:

The press is operated by an electric engine. The engine drives the crankshaft which changes over the turning movement into responding movement of the ram. The ram is fitted with the punch, to work upon the job held on the die block and bolster. Explore power presses

The electric engine supplies energy to the flywheel and this energy is moved to the ram through a clutch and crankshaft.

The different types of electric engine operated presses are:

flywheel Type

Single reduction gear type

double reduction gear type

multiple reduction gear type

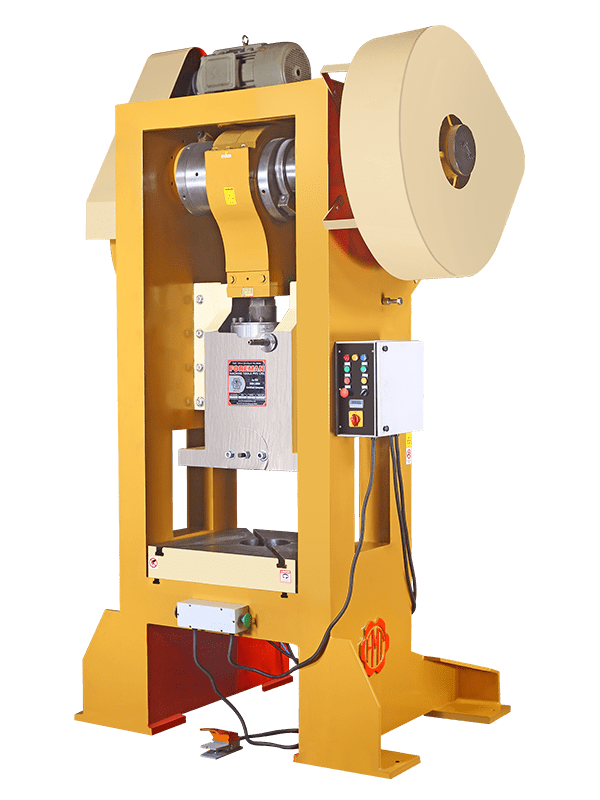

Hydraulic Press:

The hydraulic press utilizes the water or oil strain to move the slide and ramp up and down. A Pump works to supply the fluid under high pressure to the cylinder.

An accumulator system is utilized to store the fluid and afterward supply a huge volume of fluid at a consistent pressure in seconds of time. In the independent type of hydraulic presses, a collector isn’t utilized. All the energy is applied straightforwardly to the cylinder by the pump.

Hydraulic presses are accessible in limits up to 15000 tons. Hence, these presses are exceptionally utilized for drawing, expelling, penetrating and blanking metals above 3mm thickness.

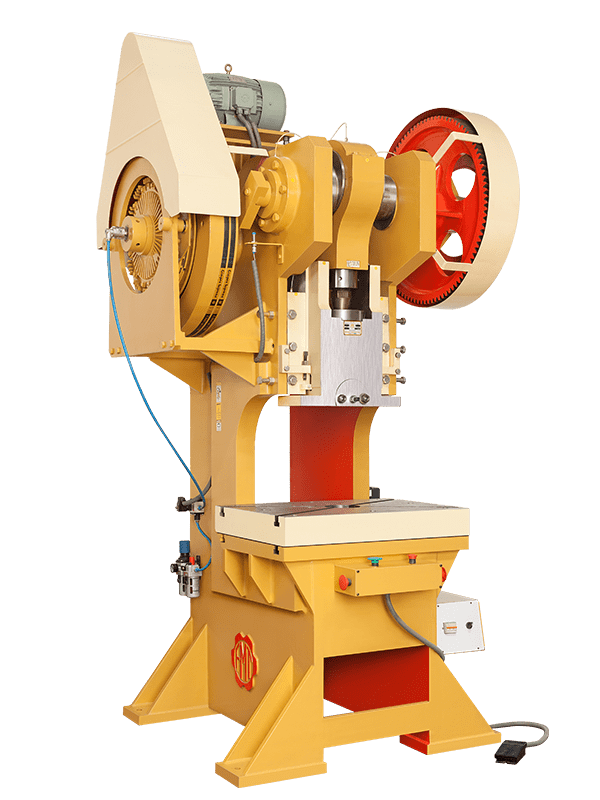

Gap Press:

A Gap-press is also called C-Press. It has an open throat that gives a magnificent gap around the dies. Such types of press permit the utilization of extremely long and wide work parts.

A punch press with an opening in the front of the frame at a level with the bed to allow the insertion of wide work or the taking care of strip stock across the bed from one side to the next

Eccentric-Driven Press:

It utilizes an eccentric to change over the rotary movement of the shaft into the up and down movement of the Ram. It is utilized where a shorter stroke length is required. The advantages of these presses are: better rigidity and less propensity of redirection when contrasted with a crank-driven press.

Read More: What Is A Punching Press? & It’s Parameters