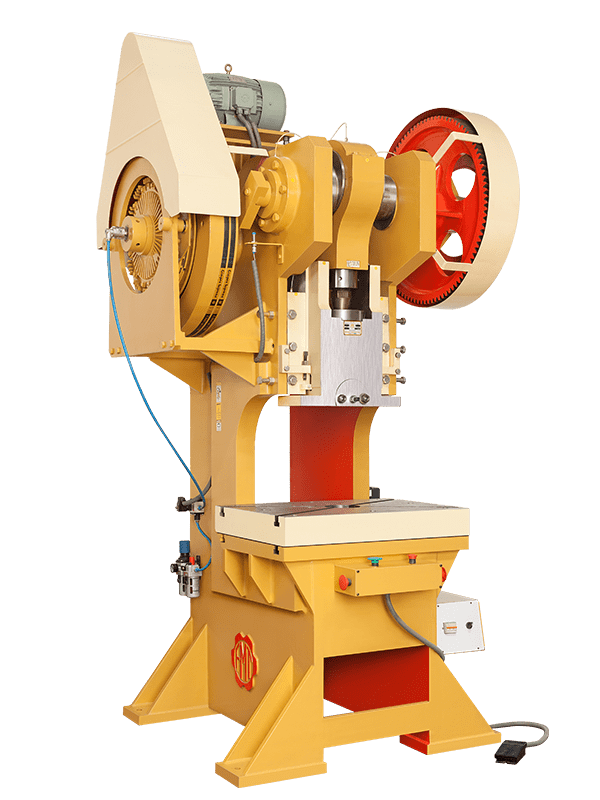

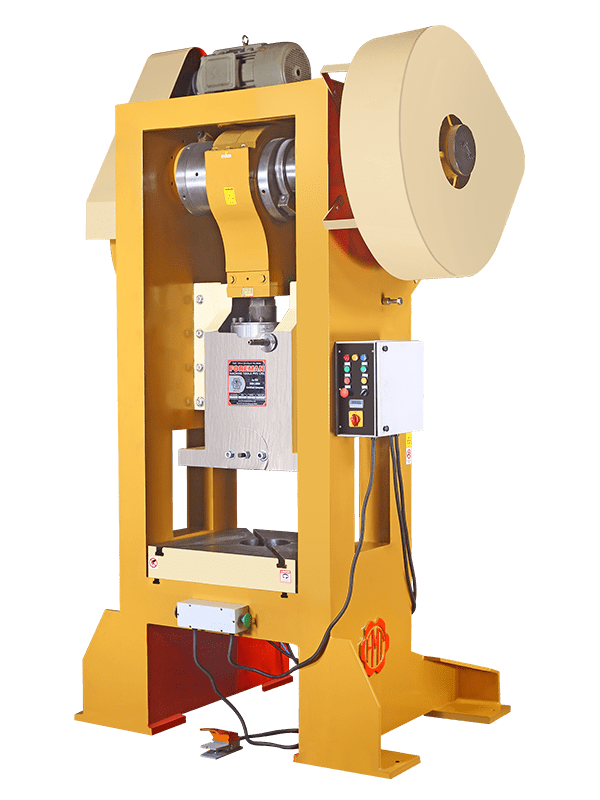

Types Of Presses

October 13, 2021

Advantages Of Punch Press

October 20, 2021Advantages

Full force stroke

The full force of a hydraulic press can be conveyed anytime in the stroke. Not just at the extreme bottom, as is the case with mechanical presses. Benefits? No recompenses for decreased weight at the top of the stroke.

In drawing activities, for example, you have the full force of the press accessible at the highest of the stroke. You don’t have to purchase a 300-ton press to get 200 tons all through the stroke. Other benefits are quicker set-ups and no time-consuming job of changing the stroke nut on the slide to accommodate various dies.

Much lower unique expense and operating costs

Hydraulic presses are relatively simple, and you might be shocked at the massive expense advantage over mechanical presses in equivalent sizes. The numerous moving parts are not many, and these are completely lubricated in a progression of pressurized oil. Breakdowns, when they occur, are usually minor; not, for example, like a broken crankshaft.

Replacements of pressing, solenoid curls, and occasionally a valve, are typical support things. Not exclusively are these parts inexpensive, but also, they are easily replaced without destroying the machine parts. This implies more uptime and lower maintenance costs.

Larger volume at lower cost

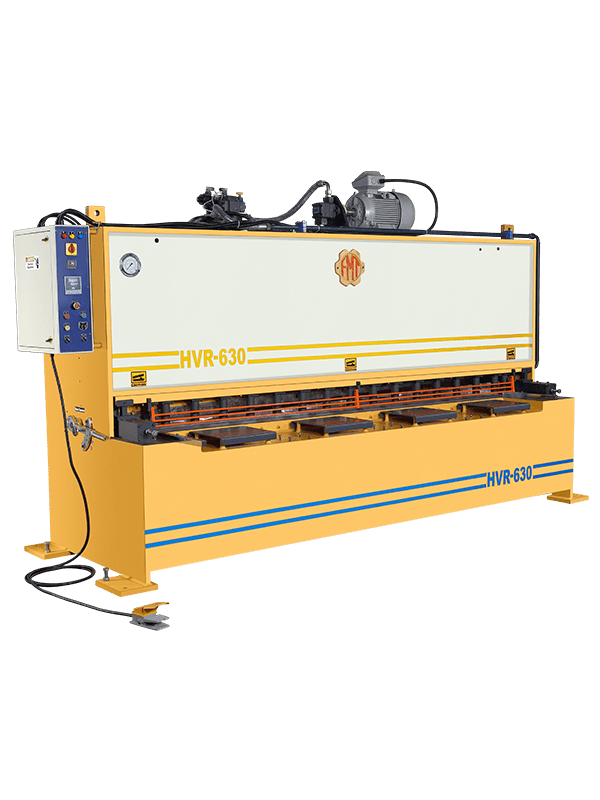

It is simpler and more affordable to purchase certain kinds of volume in hydraulic presses. Stroke lengths of 12, 18, and 24 inches are normal. Additional stroke length is not difficult to provide. Open gaps too, can be added without a lot of extra expense. Explore Hydraulic Shearing

Similarly, bigger table regions and little presses with enormous bed regions can be provided. Large 200-ton presses with relatively few beds are accessible; the weight of the press doesn’t direct what the bed size will be.

Read More: Types Of Presses

More control flexibility

Hydraulic press power is always under control. The ram force, the direction, the speed, the arrival of forces, the time of pressure dwell, all can be acclimated to fit a specific job. Jobs with a light pass can be done with the pressure turned down.

The ram can be made to approach the work rapidly, then moved to a slow speed prior to contacting the work. Apparatus life is prolonged. Clocks, feeders, heaters, coolers, and a variety of auxiliary capacities can be brought into the order to suit the work. Hydraulic presses can do far more than just go upward & downward.