Pneumatic versus Hydraulic Systems: What is the Difference?

December 6, 2021

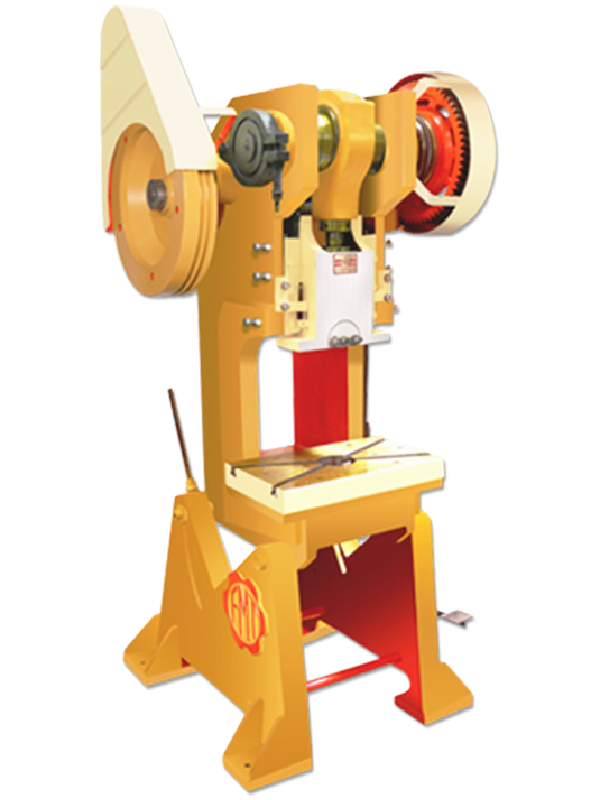

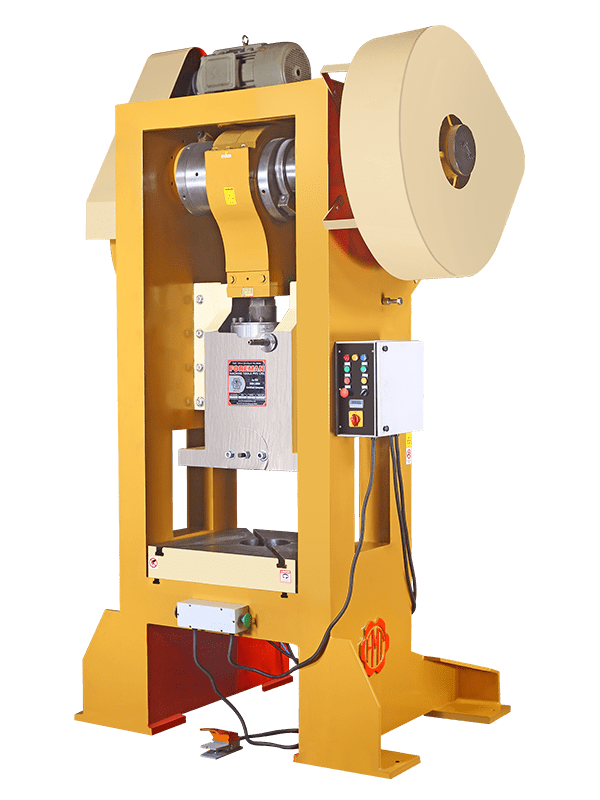

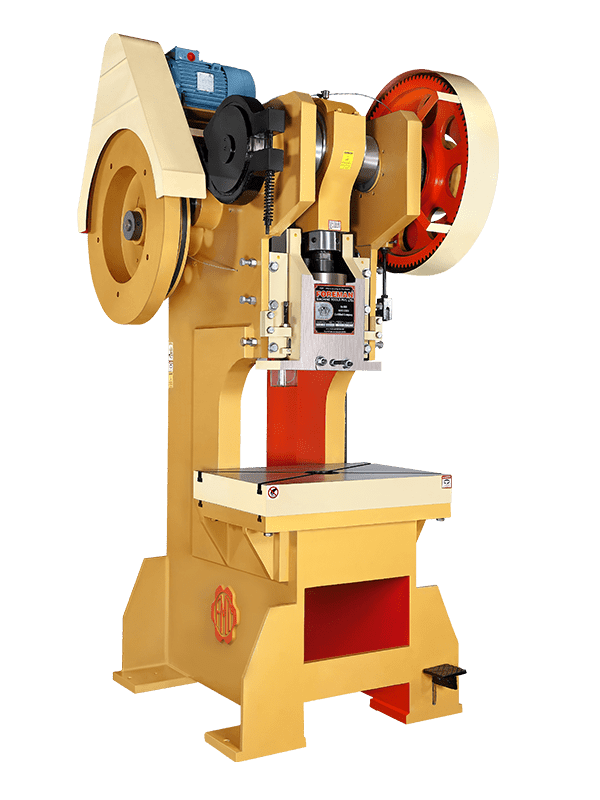

Power Press Machine Manufacturers

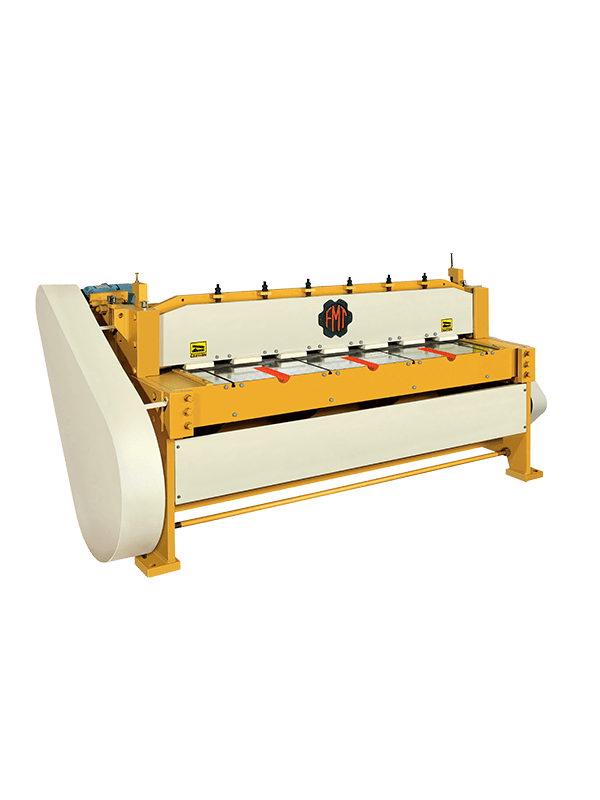

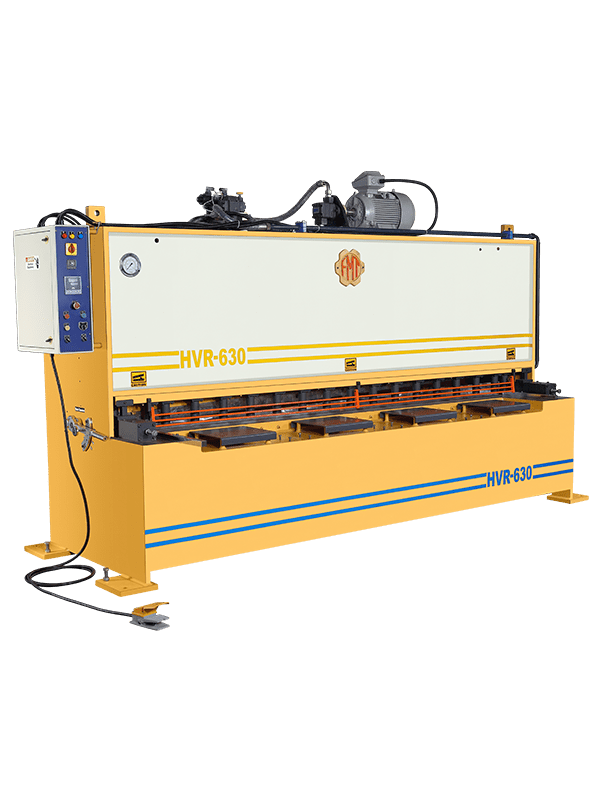

June 10, 2023When buying a hydraulic shearing machine, it is essential to conclude whether you really require a fixed rake point or a variable rake point. The rake point, or the point of the moving sharpening blade when it passes the fixed sharpened blade, determines the measure of the material the sharpened blade cuts all at once. This affects the nature of the cut, just as the measure of weight is expected to get done with the task. How about we investigate the distinction between a fixed and variable rake point.

Why Rake Point is Important

Affecting the general quality of the cut, the rake point of the sheared piece of metal decides the measure of curve and bow created.

Fixed Rake Point System

When you buy a hydraulic cutter that has a fixed rake point, the point stays set at the manufacturer setting. Hydraulic Pressure driven shearing machine makers compute the point to give the best shear quality than the scope of material thicknesses controlled by the machine’s tonnage.

Variable Rake Point System

At this point, when you choose to buy a hydraulic cutter that works with a variable rake point framework, the administrator can change the point of the rake to fit specific applications. Hydraulic Pressure driven shearing machines with a variable rake point framework is generally found in shops with thicker limit prerequisites. They might decide to utilize a high rake for cutting pieces of metal that are particularly thick while changing to a low rake point when shearing more slender materials to work on the part quality and to save power.

The Difference between a High and Low Rake point

A high rake point turns the upper edge down and can shear the material utilizing an activity like scissors. A high rake point is best utilized when careful accuracy isn’t basic. It is vital to watch the cutoff piece to guarantee it doesn’t bow, camber, or turn.

When utilizing a low rake point, the upper cutting sharpened blade drops move to the bottom corresponding to the lower sharp edge. The shearing power grows across the length of the material being cut as opposed to remaining packed in a little area. This outcome resulted in less contorting, bowing, and mutilations in the cutoff part. Machines furnished with a lower rake point require more power than shearing machines with a huge rake.

Read more: Pneumatic versus Hydraulic Systems: What is the Difference?

If you are in need of a high-quality hydraulic pressure-driven shearing machine, Foremanmachine is only the spot to begin and end your inquiry. We base every one of our designing plans on demonstrated conventional plans, just as the most exceptional shearing machine innovation.